Sustainablity at Bagru, begins with caring for our environment and artisans

From sourcing raw materials to finished products, block printing is a collective effort. It takes a village. Here’s how we keep it sustainable.

OUR PLANET:

We make biodegradable, eco-friendly, and mindful choices every step of the way

OUR PEOPLE:

We pride in providing a thriving livelihood and a fulfilling work environment to our employees

OUR ARTISANS:

We ensure they get premiums and we strive to give back through welfare programs

OUR PROCESS:

Our production process is smart and efficient. We use green energy and water harvesting and focus on minimizing as much waste as we can.

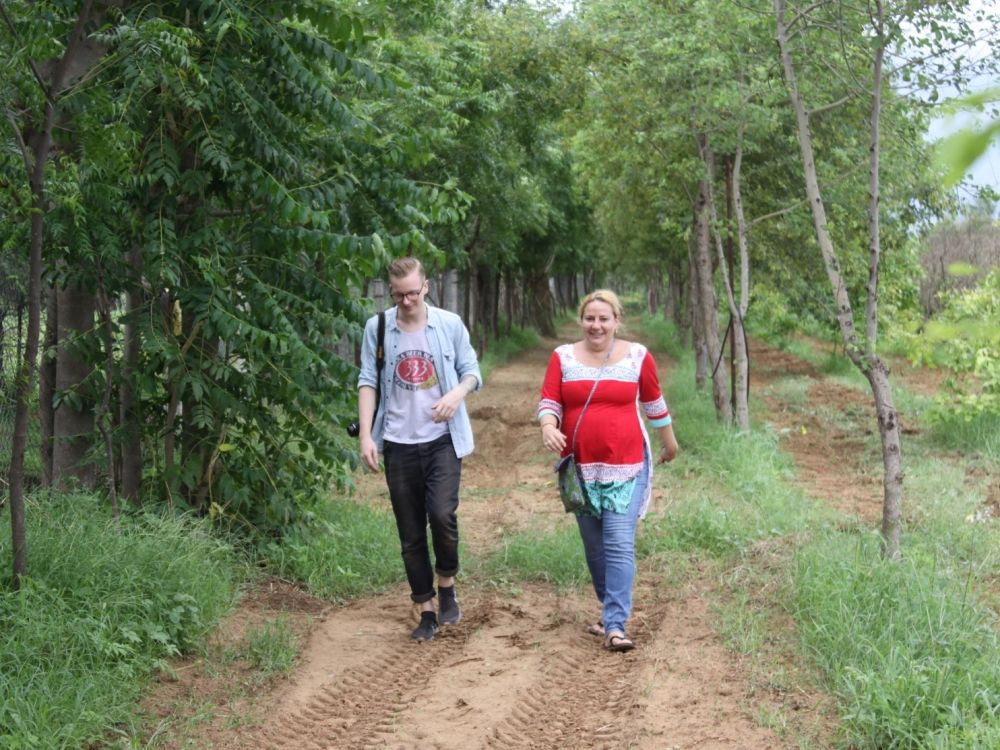

Jai Texart's Bagru Workshop - Jai Bagh

We’re an eco-conscious company

At Bagru, we take our responsibility toward the environment very

seriously. Our manufacturing process is sustainable, has a low negative

impact on ecology, and promotes the conservation of natural resources.

We start work at sunrise and shut operations by sunset.

Big on mindful and balanced living, we do not promote mindless hustle in

any shape or form—no night shifts, no overtime, no thankless toil. We

take the following measures to ensure we return to mother earth as much

as we borrow from her.

Tree Plantations

Trees are our lifelines, benevolent benefactors. They give us all

and in abundance—greenery, oxygen, fruits, herbs, clean air,

shelter, rain. They prevent soil erosion and keep the environment

cool.

Over the years, we have planted more than 2,000 trees across Bagru

village. Of these, about 1000 have survived. We continue to

nurture them with a lot of love and care.

Water Conservation

Hand block printing is a water-intensive industry. Since our water

consumption is large, it was imperative for us to use and conserve

it judiciously. All our units are therefore equipped with a

rainwater harvesting system (RWHS). It supplies about 100 lakh

liters of fresh rainwater every year to earth.

All the units also have effluent treatment plants (ETP), which

help us recycle water that we use for various supporting

activities.

Green, clean energy

To reduce our carbon footprint, we do not use fabrics made from

polyester, nylon, acrylic, or others sourced from fossil fibers.

We only use fabrics made of natural fibers. For our internal and

local transportation, we use e-rickshaws. We do not use disposable

plastic glasses/cups to serve tea to our staff/artisans.

We are also gradually reducing our dependence on electricity

generated from coal or petroleum. We have taken various steps to

switch to renewable sources and generate clean and sustainable

energy:

-

1.

Solar plants: We have installed 30 kVA solar plants (15 kVA in Bagru and

15 kVA in Sanganer unit) which takes care of 80% of our power

load.

-

2.

Solar heaters: We have installed solar heaters in our units for hot water to

cut down the need for wood (we have reduced it by 40%),

petroleum, and other non-renewable energy resources.

Locally-grown raw materials

We source raw materials that are grown locally. It helps us reduce

travel miles and the cost of our products drastically. We extract

the natural dyes that we use at the Bagru unit from flowers,

leaves, barks, roots, and gum of locally-grown trees like

pomegranate, indigo, harda, turmeric, dahura, marigold, acacia.

We also use minerals such as limestone and raw salt that are

available within 200 km of our unit. We use natural fiber-based

fabric i.e. cotton that is grown in abundance in Rajasthan and the

neighboring state of Gujarat.

No hazardous chemicals

We strictly prohibit the use of chemicals that are hazardous to air or groundwater such as paints, oil, and ammonia in our production process.

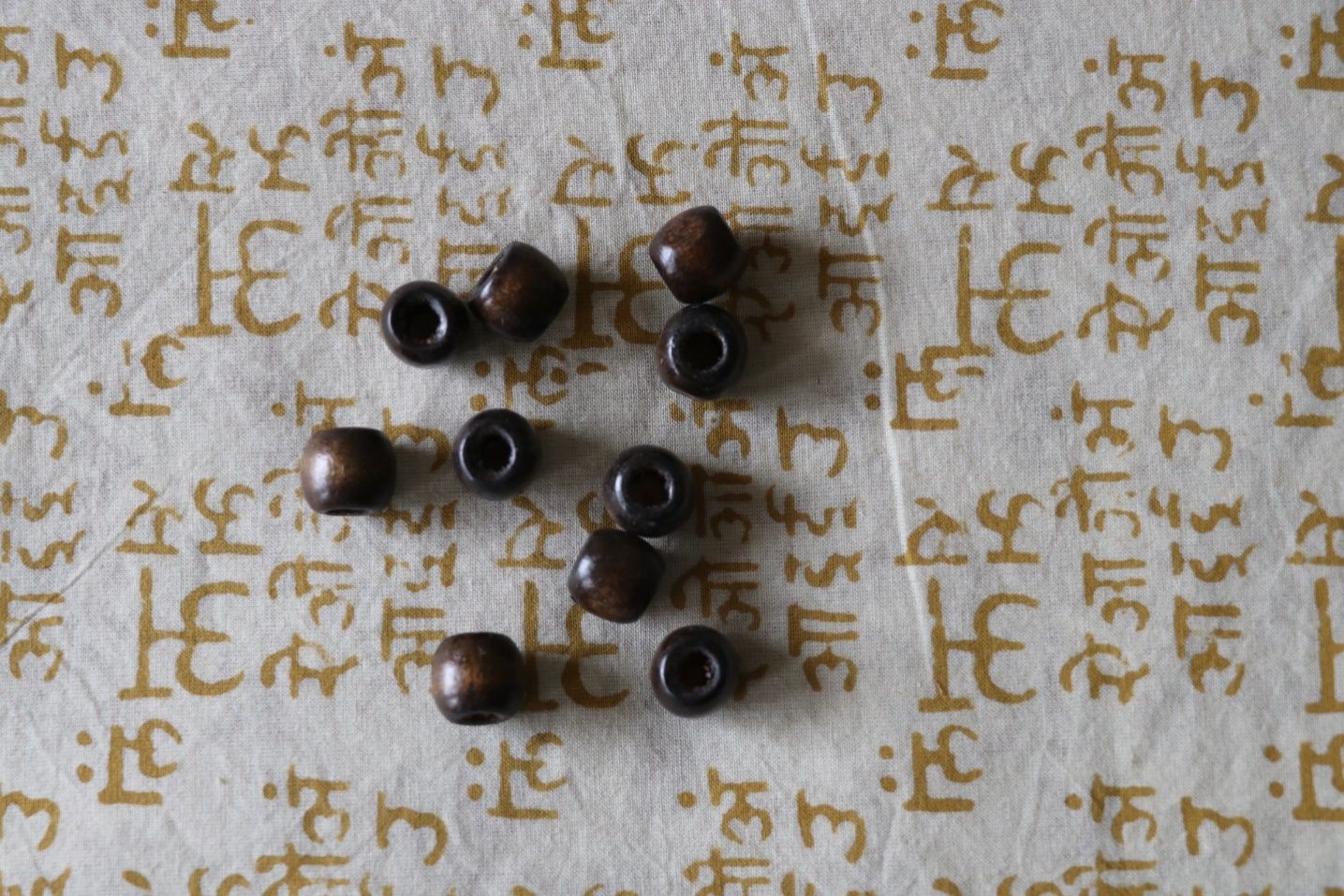

Upcycling

To manage waste efficiently, we upcycle our leftover fabrics and create useful accessories, ropes, and carpets. Most of the accessories that we use in our garments and other products are made from recycled natural materials such as wood, coconuts, horns, metals, shells, and lac.

Awareness Programme

We regularly invite industry experts and thought leaders from other related sectors to showcase to them our efforts in sustainable manufacturing and tell them about its long-term environmental and economic benefits. Under this initiative, so far we have got installed more than 200 kVA solar plants and inspired over 100 manufacturers to reduce the use of disposable, single-use plastic and create rainwater harvesting systems on their premises.

See what's buzzing at our Workshops